Sensors for measuring the deviation of piles

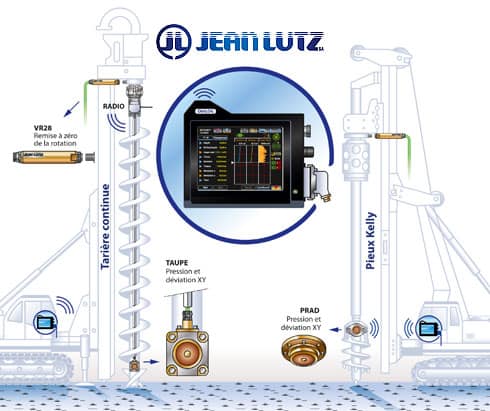

Experts in auger or Kelly piles are aware of this: the verticality of the structures may need to be carefully controlled when making secant piles and certain types of isolated piles. For this, Jean Lutz has designed two new measurement systems: Prad and Taupe sensors.

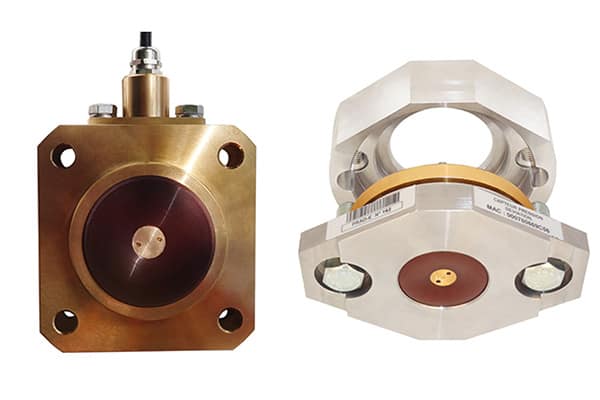

The Prad sensor fits both the auger and Kelly at the bottom of the tool. It measures the deviation and the bottom pressure: at each ascent of the drilling, the Prad transmits the data by radio to a computer and display interface installed in the machine's cabin - typically the Dialog interface.

Jean Lutz SA devices are able to manage data transfer to the supervisory offices of the company, and to receive instructions or operating procedures, and produce configurable reports.

In the case of Kelly piles, the Prad provides measurements are transmitted after each ascent, close to real time each time the bucket comes out of the excavation.

For continuous auger piles, data transfer occurs only once the pile is complete, after drilling and concreting. The operator then has all the information that will allow him to better reposition the next pile, to consider the possible deviation of just finished pile. It can also adjust the amount of concrete to be injected.

The Taupe measurement system, specific to augers, measures and transmits in real time all the information of deviation and pressure of concrete: adjustments during drilling and concreting are possible.

The transmission of data between the bottom and the head of the auger is ensured during the construction of the pile by a single-stranded conductor, which will be put in place along the auger.

Prad and Taupe sensors use advanced technologies based on accelerometers and gyroscopes.